As coating specialists who can provide coatings with non-stick and release properties, we service a number of customers who specialise in the rotational moulding of plastics. Here is how our expertise and our AF2108 specialist coating is applied to prevent costly issues from occurring in the rotational mould process.

The Challenge

Rotational moulding, also known as rotomoulding, is the production of hollow parts that involves adding a plastic powder to a mould, and then rotating and heating it at the same time. It is a process where no pressure is involved and it can be used to make a huge range of products from traffic cones to wheelie bins, tanks for storing water to kayaks and canoes, playground equipment to water butts. Almost any shape can be produced.

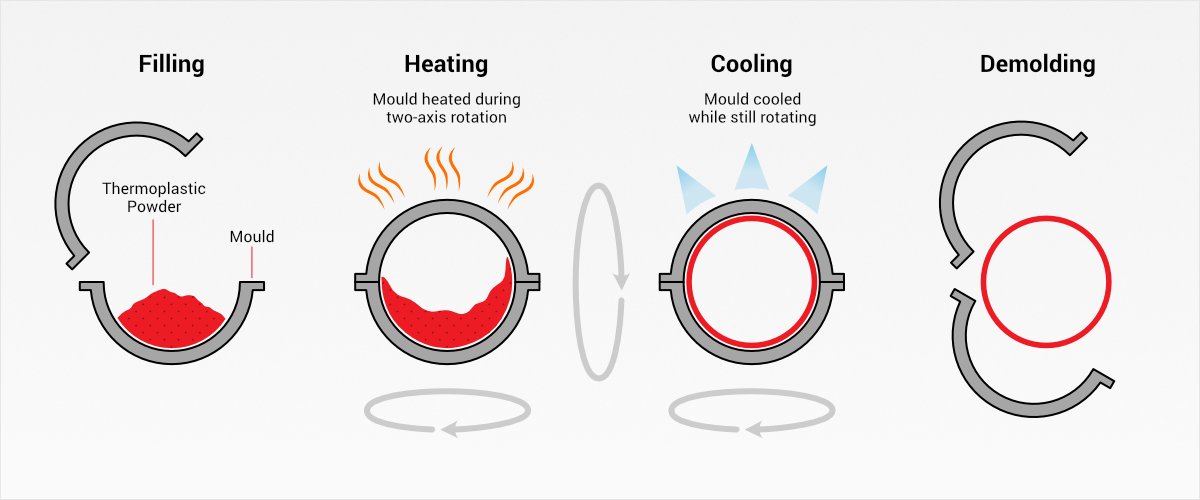

The process of rotational moulding is straightforward. A thermoplastic material (most commonly polyethylene or polypropylene) in powder form is placed in the hollow mould which is normally made from aluminium. The mould is then closed and rotated slowly on two axes whilst being heated. The thermoplastic gradually melts and ‘sticks’ to the inside of the mould. When all the polymer has melted the mould is cooled and the item becomes solid in the shape of the mould. Once cool enough, the mould is removed leaving the formed plastic item.

The Rotational Moulding Process

In order for the powdered polymer to be formed into the shape of the mould, it must melt and reform. During this process, the material becomes extremely ‘sticky’. Whilst this characteristic is essential for forming the new shape, an issue our customers find is that the polymer is difficult to 'demould', particularly when the coating inside the mould begins to deteriorate. Not only does this lead to increased processing time and additional cleaning required, but what typically happens is the ‘sticky’ polymer can leave a deposit on the mould which then ‘burns’ on and builds up over time. This causes more quality issues as well.

The Solution

Whether it is an OEM mould that requires a coating for the first time, or it's a refurbishment of an older mould, the first thing we do is prepare the surface prior to applying our non-stick release coating.

If we need to remove deposits and existing coatings from the mould, our pyrolysis oven is an extremely effective solution that allows us to remove the unwanted coating whilst leaving the original material with little to no damage.

The next stage involves our grit blasting service. Grit blasting the surface ensures that the surface is clean whilst also increasing the surface area, ensuring good adhesion for the new coating and maximises coating performance.

Finally, we apply our AFC2108 coating, which is non-stick and is designed to release the moulds without sticking or leaving polymer deposits.

The Results

Our customers have seen massive improvements to their rotational mould processes. Our newly applied AFC2108 coating has resulted in significant increases in production rates without quality issues and costly downtimes for cleaning.