Selecting the appropriate engineering plastic for industrial applications is a critical decision that can significantly impact performance, durability, and compliance. With industries such as aerospace, automotive, food processing, science and medical requiring materials that meet stringent standards, understanding the key criteria and available options is essential when it comes to choosing the right engineering plastic for your applications.

Understanding Engineering Plastic Types and Their Applications

Engineering plastics are designed to meet specific application requirements, at the same time being strong enough to withstand challenging environments. Here’s an overview of the commonly used materials in high quality engineering plastics:

|

Material |

Key Properties |

Applications |

|

High chemical resistance, low friction |

Seals, gaskets, medical devices |

|

|

High strength, temperature resistance |

Aerospace components, engine parts |

|

|

Durable, wear-resistant, lightweight |

Gears, bearings, automotive parts |

Each plastic has unique properties that make it suitable for use by different industries and in different environments. Identifying the right material starts with understanding these qualities and applying them to their potential applications.

Key Criteria for Selecting Engineering Plastics

Choosing the right material involves evaluating a number of critical factors:

1. Durability and Wear Resistance

Some materials need to endure mechanical stresses, particularly if they’re being used for high-friction applications like gears or bearings.

2. Temperature Resistance

High-performance plastics such as PEEK are essential for parts used in environments with extreme temperature demands, such as the aerospace, hydrogen and gas & oil industries.

3. Chemical Resistance

For industries like food processing or medical, PTFE offers superior resistance to chemicals and sterilisation processes. Check out our Chemical Compatibility Tool to help you choose the right materials for your needs.

4. Mechanical Strength and Flexibility

Assessing the balance between strength and flexibility is based on the needs of the application. For example, nylon provides excellent wear resistance with lightweight flexibility.

5. Compliance and Regulatory Considerations

Industries such as aerospace and medical have strict compliance standards which result in the need for ISO certifications and FDA regulations. Materials like PEEK and PTFE are often preferred because of their adherence to these standards.

Environmental and Sustainability Factors

With increasing focus on sustainability, more industries are exploring eco-friendly plastics. We manufacture high quality engineering plastics that are designed to last, significantly reducing the need to replace parts. This, combined with our commitment to environmentally-friendly solutions, helps our clients get closer to their sustainability goals without compromising on either quality or performance.

Practical Steps for Choosing the Right Engineering Plastic

Selecting the ideal material doesn’t have to be overwhelming. Follow these practical steps:

-

Define the Application Purpose

Identify the general use and specific industry requirements. -

Assess Thermal Requirements

Consider temperature ranges the material must withstand. -

Evaluate Chemical Exposure

Analyse exposure to chemicals or sterilisation processes. -

Consider Additional Criteria

Include factors like strength, weight, and environmental concerns. -

Determine the Plastic Shape

Choose between sheets, rods, or custom moulded components.

By following these steps, you can narrow down the options and make a confident choice.

Why Partner with AFT Fluorotec for Your Engineering Plastic Needs

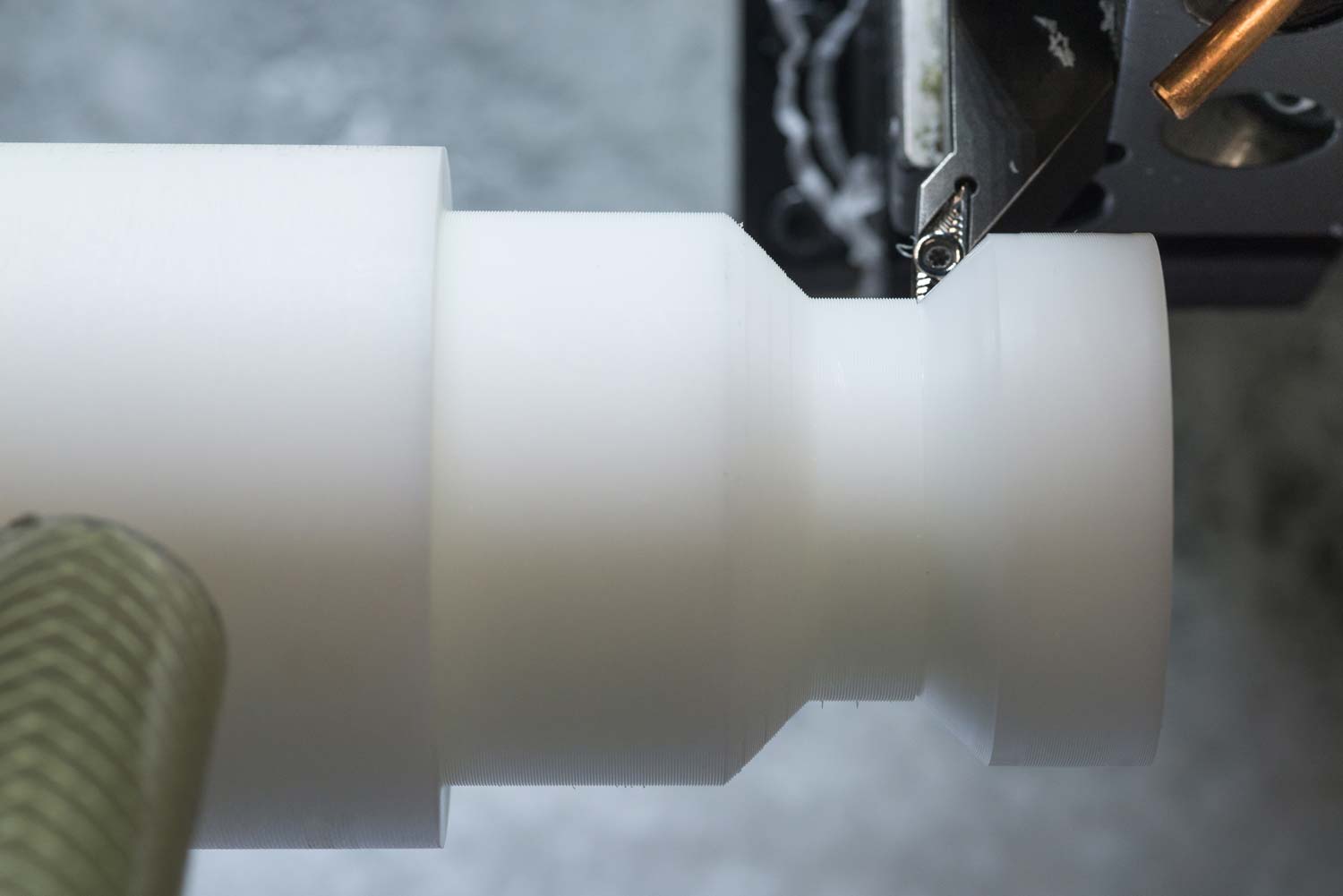

We specialise in bespoke engineering solutions using high-performance engineering plastics such as PTFE and PEEK. Our precision engineering and end-to-end capabilities combined with our focus on quality assurance and compliance have enabled us to create sometimes complex machine parts from a wide variety of materials. In many cases, we’ve been able to provide innovative solutions, delivering parts that other suppliers couldn’t.

Manufacturing in-house, we are capable of creating machined plastic parts in a range of sizes from 1mm micro parts up to products 1,800mm in diameter. We are happy to produce parts in whatever quantity you need - no job is too big or too small!

Contact us to learn more about how we can design and manufacture engineering plastic solutions for your exacting needs.

FAQs

How do I choose the right plastic material?

Start by defining your application, considering factors like temperature, chemical exposure, and compliance needs. Check out our Chemical Compatibility Tool to help you choose the best polymer if you use corrosives and chemicals. Alternatively, contact us to discuss the best engineering plastics for your needs.

What is the best plastic for engineering applications?

The best material depends on the application. PTFE is ideal for chemical resistance, while PEEK offers high strength and temperature resistance. However, other materials are available. The best thing to do is contact us and talk to one of our specialists about the best plastic for your engineering needs.

Are there eco-friendly engineering plastics?

Yes, options such as recyclable or bio-based plastics are increasingly available and suitable for specific applications.

How do I ensure compliance with regulatory standards?

Work with a trusted provider like AFT Fluorotec, which specialises in materials that meet ISO certifications and FDA regulations.

Conclusion and Next Steps

Choosing the right engineering plastic is a complex yet vital process that can drive long-term operational success. At Fluorotec, we’re here to guide you through every step, ensuring your materials meet performance, compliance, and sustainability requirements.

Contact us today to discuss your project and discover the best solutions for your industrial applications.

One of our main strengths is the vast range of fluoropolymer materials we have available. We can even work with you to create a bespoke material that's ideal for your application.