There are a number of reasons why you would need to manufacture single parts or a small batch of them. You could be developing a new product and need to test a prototype. You could need a small number of replacement parts, or simply only need a very few niche parts for a specific purpose. Or perhaps you need a product with exacting specifications and small-scale production is the best way of getting the high levels of production and quality control you need.

The Importance of Custom Solutions in R&D

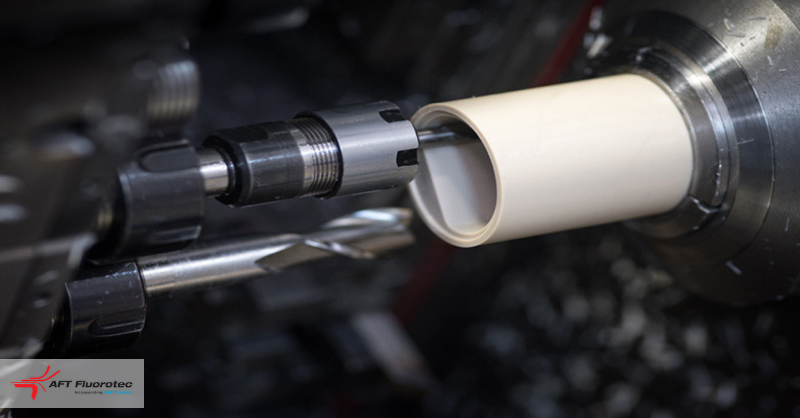

Research and development is a crucial part of the manufacturing process and when you’re developing new products it’s important to get every detail spot on. When it comes to manufacturing prototype parts, the ability to get custom parts made quickly and to your exacting specifications is crucial. Computer Numerical Control (CNC) machining is by far the best method for doing this. Using CAD designs, the technology controls the lathe which means precision is guaranteed when it comes to creating even complex parts. And they are much quicker than traditional machine shops.

No matter how small or complex the CNC machined part you need, CNC machining services are an ideal solution for the manufacture of prototype parts. It enables us to produce high quality parts with tight tolerances quickly and cost effectively, enabling you to refine your prototypes as many times as you need to.

Key Challenges Faced by Innovators

The main challenges innovators face are finding the right manufacturer to help you design and produce your machined prototype. You need to find a company that invests in high spec CNC machines that can deal with the complexity of the parts.

How CNC Machines Aid Prototype Testing

CNC machining is a hugely effective way to produce high quality prototypes and complex parts. The lathe is controlled by the computer, resulting in precision-engineered parts from your designs, and can be adjusted and improved upon until you get the perfect part. The CNC machining process means every part subsequently produced will be identical to the approved prototype, even if your needs grow to large scale production.

Industries that use CNC machining to create the kind of high quality prototypes needed to include aerospace, energy, automotive, and food processing.

Customisation Needs

You also need a company that specialises in machining in the materials you require, for example engineering plastics. You need specialists to help you with the best material for the job, who also have the expertise to create a bespoke material that is better suited to the task it needs to do.

Lead Times

Sometimes a quick turnaround is essential, and it’s not always easy to find a manufacturer willing to take on an urgent project for a prototype or small batch run. Any delays in creating the parts can have a knock-on effect on your project in the long run which could prove costly in terms of finances and brand awareness.

How Flexible Suppliers Address The Pain Points of Customisation and Small Batch Production

Scalability Issues

Much of the time, companies needing just one CNC machined part or a small batch find it difficult to find a manufacturer with the flexibility and willingness to take the job on. Small batch production is the perfect next step from the prototype stage as it enables you to continue testing the parts without committing to large-scale manufacturing. Which is where CNC machining services come into their own. Once the part has been refined, it is also beneficial to use the same manufacturer to scale up production as you already know you will get the quality you need, with the additional benefit of maintaining consistency throughout the manufacturing process.

Flexible suppliers are also beneficial for small and growing businesses. When you can order exactly how many parts you need, there are no problems with storage or waste which occur if you buy from manufacturers that only work in large batches. While initially the cost per part may be lower, the initial investment could be more than you can afford upfront, and over time the cost per part could accrue, especially if your needs change and you no longer need that particular unit. By finding a supplier that is flexible enough to provide as many or as few parts as you need at any one time, including mass production, you will always have a trusted partner who can supply your needs as and when you grow your business.

Advantage of a Tailored Approach

There are many advantages to having your parts tailor made, efficiency being the main one. A manufacturer offering custom solutions will have the equipment and expertise you’ll need to produce to your exacting requirements. With each part produced perfectly, you can confidently manufacture the exact number of parts you need, without having to manufacture more to cover parts with weaknesses or imperfections.

You’ll not only be assured of the quality, you will also be confident that each part is compliant with industry needs, accreditation and ISO certifications.

How to Choose the Right Supplier

If you need to create a high quality prototype, a small batch of parts, or high quality precision-made parts, look for a supplier with a proven track record in your specialism.

Why Choose AFT Fluorotec

AFT Fluorotec has been manufacturing engineering plastic precision parts for nearly 30 years. Consistent quality is hugely important to us, which is why we have a number of ISO certifications. Our CNC machining services are ideal for rapid prototyping and producing machined parts of the highest quality. We appreciate that in some industries, even the smallest parts can have a major impact on the overall integrity of the equipment, which means they have to be made of the strongest materials and precision engineered to fit perfectly.

We are an innovative, forward-looking company and have invested in state of the art CNC machining equipment to help us manufacture parts to extraordinarily high standards.

We take the time to understand our clients’ needs and will not only manufacture parts to their exacting requirements, we will also customise the materials to ensure they are perfect for the job. Click here to find out more.

We are renowned for our flexibility as well as the quality of our work, and can often take on urgent jobs and turn them around very quickly.

And if you’re looking for a supplier that is striving for sustainable solutions, you’ve come to the right place. We take our corporate responsibility seriously and have invested heavily in solar energy, as well as many other smaller-scale actions that contribute towards our green credentials.

If you would like to talk to one of our specialists about an upcoming or urgent job, call us on 01992 515880.

FAQs

Can small-scale testing still maintain quality and compliance?

Absolutely! Our designers and operators ensure that each CNC machine part is manufactured to extremely high standards, whether you’re creating just one prototype, doing a small-scale run, or manufacturing a large batch.

Is small-batch production cost effective?

Yes, it is. While the initial cost per part is more expensive than a large manufacturing run, small-batch production can turn out to be extremely cost effective in the longer term. This is because of the greater attention to detail that is possible with a smaller batch - they are manufactured by precision CNC machining and there is also more attention to quality control which means each part will fit exactly and be robust enough to last for years. As they’re less likely to malfunction or break, you’ll make future savings in terms of costs of repairs and expensive production downtime.