Every seal manufactured at AFT Fluorotec is designed and made specifically to suit the application.

Whilst we work around typical designs and groove dimensions for much of what we do, it is not a full picture of all we do. Many of the seals we design and supply are specials – the difficult applications, the extremes, often specific to particular products and service conditions and very often oil and gas related.

HPHT Valve Stem Seals

HPHT Valve Stem Seals

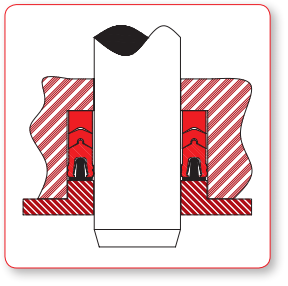

AFT manufactures a wide variety of high-pressure high temperature high performance valve stem seal assemblies and gland packings. None of these is standard although many follow a standard theme. Featured here is an example of a high-pressure gate valve stem seal assembly, tested at 15000 PSI and -29°C to +180°C.

These products are extremely versatile and somewhat modular. The V-ring can be made in PEEK, filled PTFE or even an elastomer for certain applications. They can be designed with more than one V-ring in each stack and they don’t have to be the same material to improve lower and higher temperature performance.

HPHT Gate Valve Seat Seals

HPHT Gate Valve Seat Seals

All of our spring energised rod and piston seals are available as face seals however certain extreme applications require extreme seals.

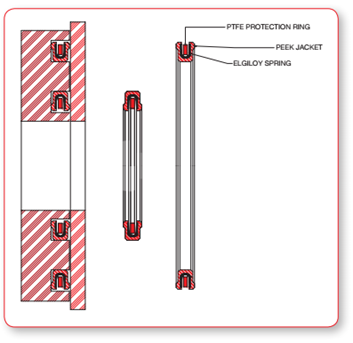

AFT design and manufacture HPHT gate valve seat seals for valve manufacturers worldwide. Typically these comprise an AF801 Victrex™ PEEK jacket energised with an Elgiloy® spring with a PTFE insert to prevent permanent deformation of the seal and spring should something go wrong.

This means that even after an episode of rapid decompression, the seals will perform as normal. These high performance face seals are not limited to gate valves. They can be used in any extreme applications where a high performance semi static seal is required.

Let's Talk ABout Custom Valve Seals

If you have a specific design in mind, or would like to send us your valve seal requirements so we can advise on the best solution, get in touch with our Technical Team through the form below.