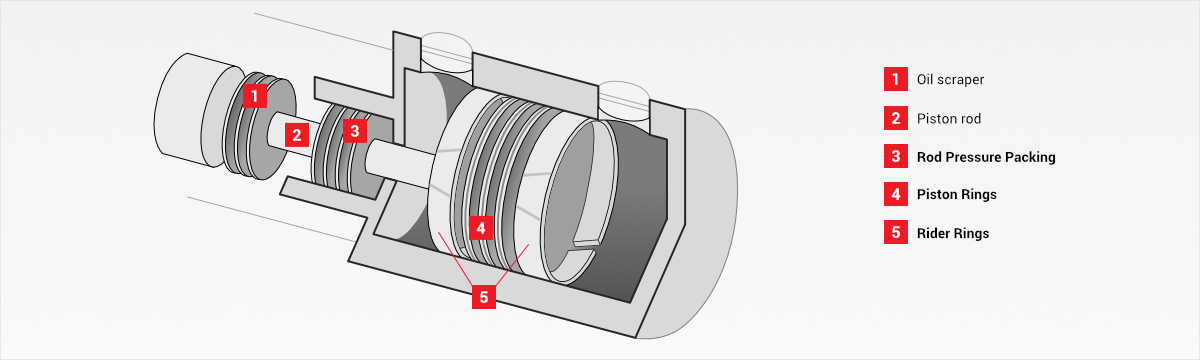

One of the biggest uses of our specially created PTFE and PEEK filled grades can be found in the compressor industry. Piston and rider rings, which can be found in all types of compressors are almost exclusively made out of PEEK & PTFE compounds, which AFT Fluorotec have been specialising in for a number of years.

compressor appropriate materials

We pride ourselves on our expert knowledge of the compressor parts industry, providing a wide range of compounds suitable for your application. You'll find further data relating to each of our grades suitable for use within gas compressors below. AFT can modify these compounds to meet the specific operating performance of your application, and we can offer advice and help to ensure it is suitable for its intended use.

AF106 is a lubricated glass-filled PTFE compound. Due to the glass content, AF106 is somewhat abrasive and care should be taken to not match AF106 with soft mating surfaces. Low creep and low wear, AF106 is the preferred material for natural gas applications. Recommended for both lubricated and non-lubricated applications for piston rings, rider rings, and rod packing.

TENSILE STRENGTH: 21-24 MPa

ELONGATION: 260-500%

APPROPRIATE SEALING COMPONENT: Piston Ring, Rider Ring, Rod Packing

| COMPRESSOR OPERATING CONDITIONS | |||

| TYPICAL GAS APPLICATIONS | LUBE | NON-LUBE | NON-LUBE DRY |

| Air | |||

| CO2 | |||

| CO | |||

| CXHY |

|||

| H2 Pure |

|||

| H2 Mixes | |||

| Ethylene |

|||

| Refrigeration |

|||

AF203 is a compression moulded carbon/graphite filled PTFE compound with good mechanical and wear properties and resistant to most chemicals. A legacy choice for both lubricated and non-lubricated compressor piston rings, rider rings and rod packing, it remains a primary choice.

TENSILE STRENGTH: 14-20 MPa

ELONGATION: 85-180%

APPROPRIATE SEALING COMPONENT: Piston Ring, Rider Ring, Rod Packing

| COMPRESSOR OPERATING CONDITIONS | |||

| TYPICAL GAS APPLICATIONS | LUBE | NON-LUBE | NON-LUBE DRY |

| Air | |||

| CO2 | |||

AF204 is a premium material suitable for the majority of non-lube applications, wet gas and oxygen service and all lubricated service. Excellent wear properties, often double the lifespan of traditional carbon filled PTFE compounds. Typical applications include refinery gas, refrigeration gas, hydrocarbons, oxygen and air.

TENSILE STRENGTH: 15 MPa

ELONGATION: 300%

APPROPRIATE SEALING COMPONENT: Piston Ring, Rider Ring, Rod Packing

| COMPRESSOR OPERATING CONDITIONS | |||

| TYPICAL GAS APPLICATIONS | LUBE | NON-LUBE | NON-LUBE DRY |

| Air | |||

| O2 | |||

| NOX | |||

| CO2 |

|||

| CI2 | |||

| NH3 | |||

| CXHY | |||

| H2 Mixes |

|||

| H2S | |||

| HCI | |||

| SO2 | |||

| Vinyl chloride & similar | |||

| Ethylene | |||

| Ethylene oxide | |||

| Refrigeration | |||

AF225 is a proprietary material offering very high modulus and low creep. Primarily rider rings, piston rings and rod packings in non-lube “dry” and “bone dry” gas compressor applications with a dew point as low as minus 40°C are where this material excels. Excellent performance in dry ethylene, hydrogen, dry natural gas.

TENSILE STRENGTH: 10 MPa

ELONGATION: 100%

APPROPRIATE SEALING COMPONENT: Piston Ring, Rider Ring, Rod Packing

| COMPRESSOR OPERATING CONDITIONS | |||

| TYPICAL GAS APPLICATIONS | LUBE | NON-LUBE | NON-LUBE DRY |

| Air | |||

| NOX | |||

| N2 | |||

| CO2 |

|||

| NH3 | |||

| CXHY | |||

| H2 pure | |||

| H2 mixes | |||

| Vinyl chloride & similar | |||

| Ethylene | |||

| Ethylene oxide | |||

AF226 is a multi-filler material which despite advancements in PTFE material science, remains a primary choice and well established PTFE based material for compressor applications where air, methane, ethylene, propylene or hydrogen is present.

TENSILE STRENGTH: >16 MPa

ELONGATION: >140%

APPROPRIATE SEALING COMPONENT: Piston Ring, Rider Ring

| COMPRESSOR OPERATING CONDITIONS | |||

| TYPICAL GAS APPLICATIONS | LUBE | NON-LUBE | NON-LUBE DRY |

| Air | |||

| NOX | |||

| CO2 |

|||

| Cl2 | |||

| NH3 | |||

| CXHY | |||

| H2 mixes | |||

| H2S | |||

| HCI | |||

| SO2 | |||

| Vinyl chloride & similar | |||

| Ethylene | |||

| Ethylene oxide | |||

| Refrigeration | |||

AF403 performs particularly well at high discharge temperatures and is recommended for non-lubricated air, oxygen and gas compressors. Similar to AF410, AF403 offers excellent conductivity/heat dissipation. As well as general high-temperature applications, this is a great choice where high ambient temperatures are present.

TENSILE STRENGTH: 2,320psi

ELONGATION: 350-420%

APPROPRIATE SEALING COMPONENT: Piston Ring, Rider Ring, Rod Packing

| TYPICAL GAS APPLICATIONS | LUBE | NON-LUBE | NON-LUBE DRY |

| Air | |||

| O2 | |||

| NOX |

AF410 is a grade specifically developed for high temperature and high-pressure air/wet air compressor applications, piston rings, rider rings and rod packings. AF410 has better thermal conductivity than carbon and glass-filled PTFE compounds. AF410 offers a very low and stable rate of wear, even when operating saturated at high temperatures.

TENSILE STRENGTH: 30 N/mm2

ELONGATION: >260%

APPROPRIATE SEALING COMPONENT: Piston Ring, Rider Ring, Rod Packing

| COMPRESSOR OPERATING CONDITIONS | |||

| TYPICAL GAS APPLICATIONS | LUBE | NON-LUBE | NON-LUBE DRY |

| Air | |||

| NOX | |||

AF803 is a very high-performance hot moulded polymer material for lubricated very high-pressure applications. Excellent performance in gas applications including hydrogen, ammonia, carbon dioxide and ethylene. A proven high performer in reciprocating compressors worldwide and is also compatible for use with metallic packings.

TENSILE STRENGTH: 141 MPa

ELONGATION: 2.2%

APPROPRIATE SEALING COMPONENT: Piston Ring, Rider Ring

| COMPRESSOR OPERATING CONDITIONS | |||

| TYPICAL GAS APPLICATIONS | LUBE | NON-LUBE | NON-LUBE DRY |

| Air | |||

| CO2 | |||

| CXHY |

|||

| H2 Pure |

|||

| H2 Mixes | |||

| Ethylene |

|||