Whilst all of our coating solutions are designed with durability at the forefront, there will inevitably be a time when a product's coating reaches the end of its lifespan and will need to be reapplied.

We have a range of industrial paint removal solutions such as grit blasting, temperature-controlled burn off (pyrolysis) and chemical stripping, which allows us to properly treat and clean your product before reapplying a coating. This allows you to extend your product's lifespan whilst saving you money by eliminating the need to purchase new replacement parts.

REUSE, NOT REPLACE

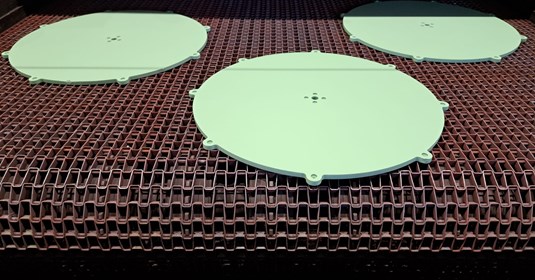

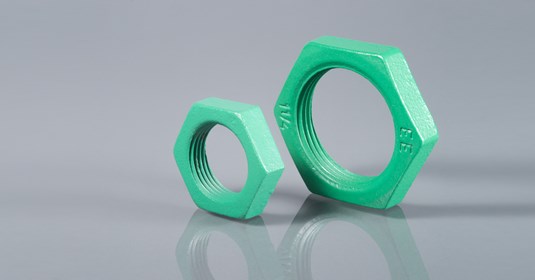

Our coating solutions are applied to products across a wide range of industries that have to withstand rigorous use and extreme environments, from industrial bakeware/food processing equipment used in demanding production applications to pharmaceutical/chemical/oil and gas equipment where chemical/corrosion protection, low friction and non-stick properties are required.

Our industrial paint and powder stripping services only remove layers of applied paint or powder coating, with the base surface, left untargeted. This ensures the product material is not compromised or damaged in any way and is left in the best condition to be recoated.

No project too big or too small

We have 5 blast rooms all with different grits and medias to enable us to blast metal components up to almost any size. We have 5 blast rooms all with different grits and medias to enable us to blast metal components up to almost any size.

Industrial Paint & Powder Stripping

Have a query about our industrial paint and powder stripping services? Get in touch with our team of experts.

Our team are happy to answer any questions you have about using our products and services in your next project. Fill in your details below and we'll be in touch.