Abrasive grit blasting, also known as sandblasting, is a common surface treatment process which can be used on any metal surface which is being prepared for a paint job or coating.

By creating a smooth surface finish, abrasive blasting removes the pits and cracks that frequently harbour moisture and contaminants – and which can cause problems with paint adhesion down the line. It also removes the mill scale and soluble salts that can lead to rust build-up under the paint, which can ruin the metal surface itself as well as the coating.

RANGE OF BLASTING OPTIONS

There are a number of different blasting techniques that we can offer, depending on the surface on which the work is being performed. Our variety of abrasives means that we have the medium for almost any blasting job. The most abrasive are shot blasting (with metal shot) and sand blasting (with sand). Glass bead blasting and plastic media blasting (with ground-up plastic stock or walnut shells) can be used for a milder blasting solution.

-

Aluminium Oxide Grit Blasting

Due to its high etch properties, its ability to be recycled and its fast working speed, aluminium oxide is an extremely popular media that we offer in our grit blasting service.

-

Steel & Chilled Iron Grit Blasting

Steel & chilled iron grit blasting is a low cost and efficient method of removing surface coatings.

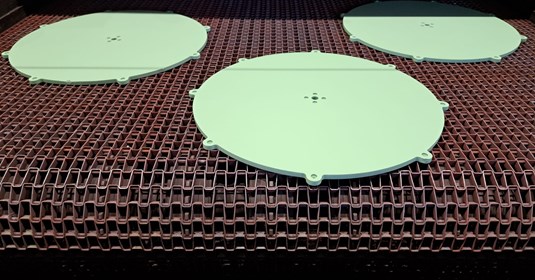

EFFECTIVE SURFACE TREATMENT

We have 5 blast rooms all with different grits and medias to enable us to blast metal components up to almost any size. This enables us to use grit blasting for things such as vehicle restoration, construction steel fabrication amongst many others.

GRIT BLASTING

Get in touch with our team of experts to discuss your project.

Our team are happy to answer any questions you have about using our products and services in your next project. Fill in your details below and we'll be in touch.