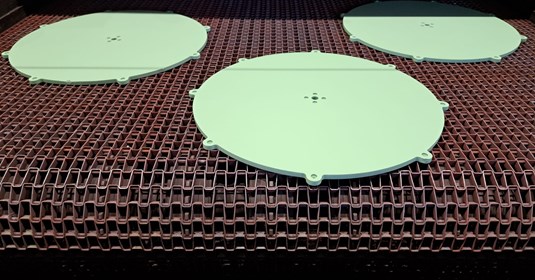

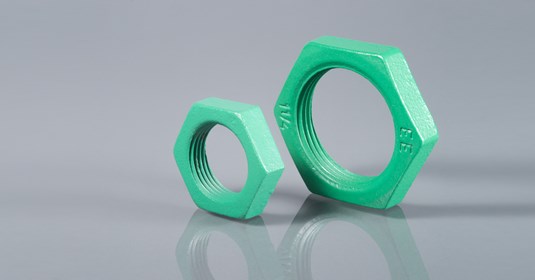

Here at AFT Fluorotec, our bead blasting surface finishing service is another area of expertise in addition to our surface preparation offering.

Bead blasting involves removing surface deposits and unwanted coating layers by applying fine glass beads at high pressure (using compressed air) to the surface of the material or component without damaging the surface and removing old powder coating and/or corrosion and producing clean and prepared metal surfaces.

It is commonly used on stainless steel fabrications that are used for processing and presentation in the food industry, luggage racks on trains and control boxes under trains.

When bead blasting is applied to a surface, no metal is removed from the surface. This is in sharp contrast to what happens to the surface of the metal during grit or shot blasting. The matt appearance is made by the impact of the beads producing tiny, smooth-edged craters as the initial surface of the metal is moved slightly. This metal movement work hardens the metal, which induces surface compressive stresses. Therefore, along with the completely uniform satin finish, the increased surface compressive stresses also lead to improved surface hardness, an increase in stress corrosion crack resistance, whilst also improving fatigue resistance.

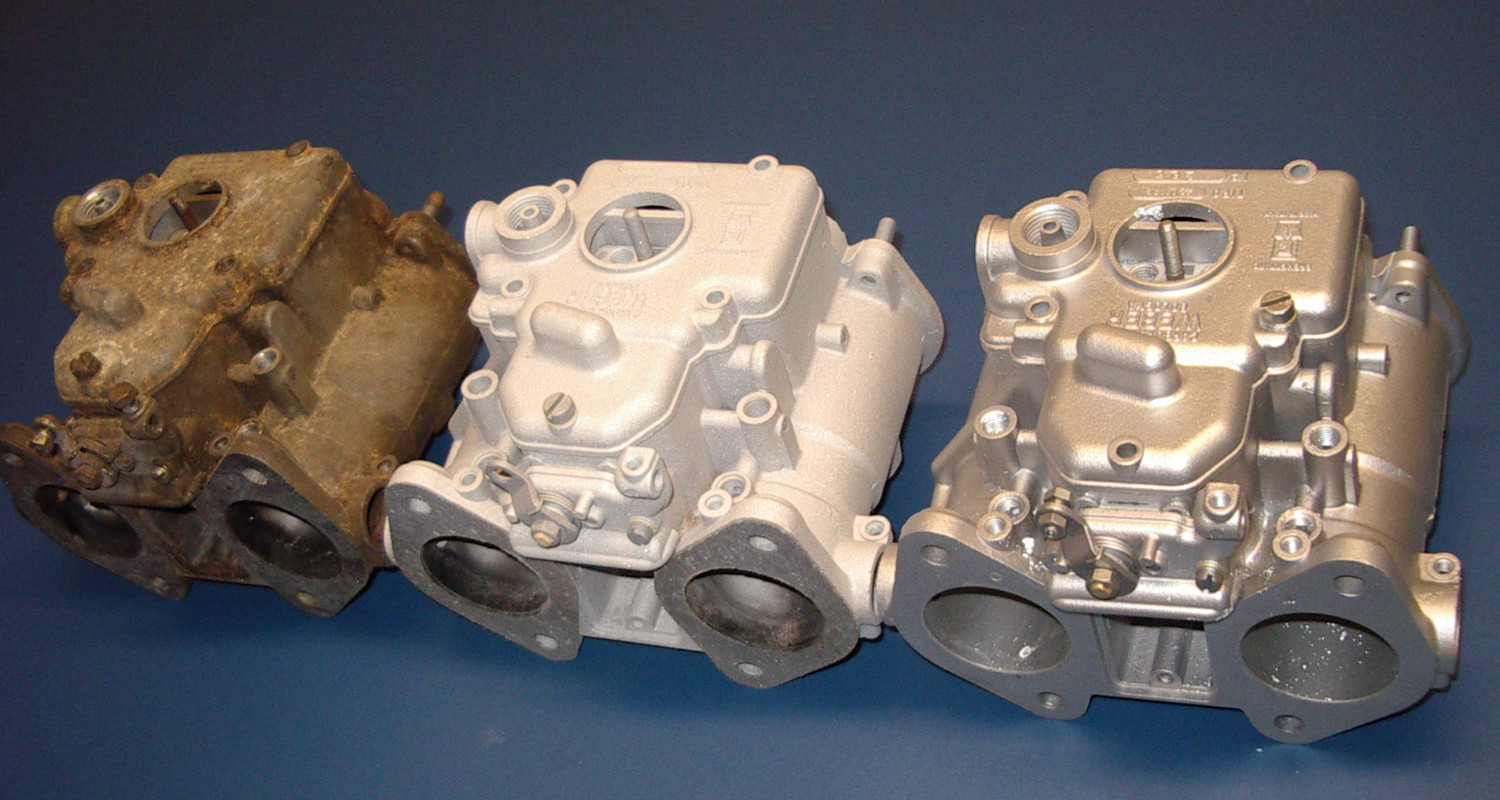

Glass bead blasting is also used in the classic car industry to remove paint from parts during restoration. In this area, bead blasting is often the preferred method as it provides a uniform surface finish on machined parts.