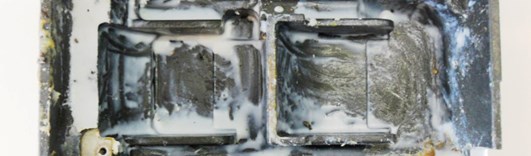

We've created AFC 2103, a low friction coating containing MoS2 (molybdenum disulphide) and PTFE providing excellent dry film lubrication whilst maintaining a low coefficient of friction. This enables our clients to use products where a secondary release agent is not advisable.

Our anti friction coatings provide friction control and surface release solutions for a wide range of industrial applications where liquid lubricants cannot be used. By working closely with our key suppliers, we can engineer precise formulations to provide customised options that meet with your exact requirements.

If you let us know your operating conditions and service requirements, we can select the right coating for the job.

What are the benefits?

By reducing wear, galling, and excessive heat generation on components gives reduced maintenance cost, machinery down time and operating limitations.

These types of low friction coatings provide effective lubrication in a wide range of loads, in many cases exceeding 150,000 psi (10,500kg/cm²). They provide friction reduction and control in harsh conditions and are suitable for tough mechanical applications. The coatings are thermally cured and bonded to the base metal of the coated part.

Our service is delivered by an experienced skilled workforce and backed up by a comprehensive quality system and coating testing facility.

- Bearings

- Chains

- Chutes

- Fasteners

- Gears

- Hydraulic parts

- Locking components

- Oil field connectors and couplings

- Oscillating parts

- Piston rings

- Rubber O Rings

- Shafts

- Sliding parts

- Sprockets

- Sub-sea hardware

- Tappets

- Threaded components

Low Friction Lubricated Coatings

Contact us to discuss our low friction and self-lubricating coatings.

Our team are happy to answer any questions you have about using our products and services in your next project. Fill in your details below and we'll be in touch.